Spend any time with Japanese performance cars and you are made aware that wheels are not simply some circle of metal- they determine the entire theme of the build.

An appropriate selection of wheels and tires brings the steering into focus, carves seconds off lap times, and can provide a car with the attitude it earned.

The term JDM Wheels carries weight because the brands behind it earned that reputation through engineering discipline, motorsport miles, and a design language that never seems to age.

Below is a deep, enthusiast-grade guide that breaks down why JDM Wheels stand apart, what that means on the road and track, and how to buy wisely without falling for hype.

Some background about the phrase: Before we jump into the seven reasons, it may help to mention what the phrase tends to cover.

JDM Wheels typically refers to wheels designed and manufactured by Japanese companies with parts and processes rooted in Japan’s automotive culture names like RAYS (Volk Racing, Gram Lights), Enkei, Yokohama Wheel (ADVAN Racing), WedsSport, and Work.

These firms assemble wheels on kei cars, as well as hot hatches and time attack nightmares, and GT cars.

The unifying factor is their desire to achieve strength-to-weight, repeatable quality, and fitments which are geared towards practical driving.

Engineering Culture That Treats Weight Like the Enemy

Lightening up the unsprung mass is worth its weight in gold in the first 100m. A reduction in weight at each corner allows the suspension to track the road more easily, lowers turn-in, and tightens braking response.

This is not marketing gibberish, and it is physics.

Why is un sprung mass critical? This primer article by Car and Driver explains in layman’s terms how a reduction in un sprung mass improves ride quality and handling (Car and Driver: Suspension Tech 101).

JDM Wheels attack mass in smart places: spoke geometry, inner barrel thickness, and hub pads are trimmed with purpose, not guesswork.

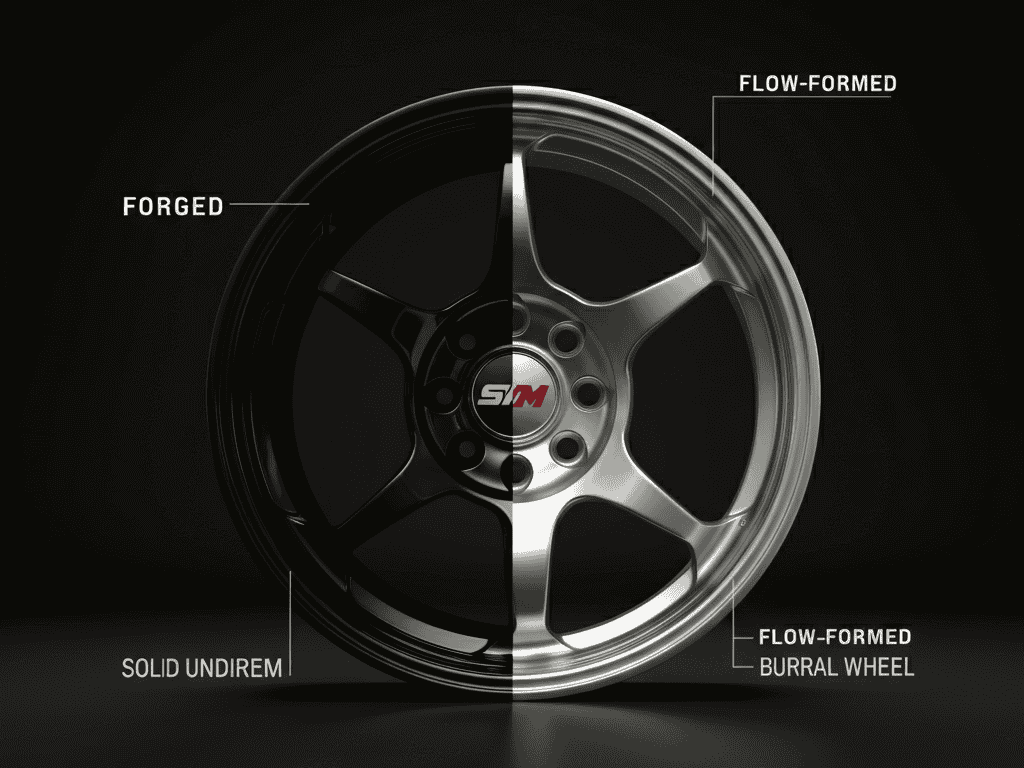

Forged models condense the grain structure of the aluminum such that the same strength is obtained with a lesser amount of material.

Barrels of the tubeless flow-forming variety not only stretch and squeeze the metal at the rim, giving it more toughness where loads peak, but don’t turn the entire wheel into a boat anchor.

What you end up with is a wheel that has a lively feel, without other costs taken out of the durability of the wheel in daily use.

Not Photoshoots, Real Motorsport Miles

You’ll find JDM Wheels under cars running in Super GT, Super Taikyu, time attack, and drift competition.

That is important because heat cycles, curb strikes, and 30-lap stints stress weak points you do not encounter on a commute.

It is not unusual to see these firms refining designs after a season of racing- tweaking spoke cross-sections, bead-seat shapes, and even valve pocket relief to provide better airflow, maintaining brake cooling.

The street versions regularly obtain the trickle-down benefits: thinner pockets where the barrel connects with the spoke, knurling at the bead modified to stop tire slip at full launch pressure, and barrel shapes that clear wider calipers without using mock spacers.

A significant difference is that those updates are not random. Japanese wheel manufacturers take racing as a rolling lab.

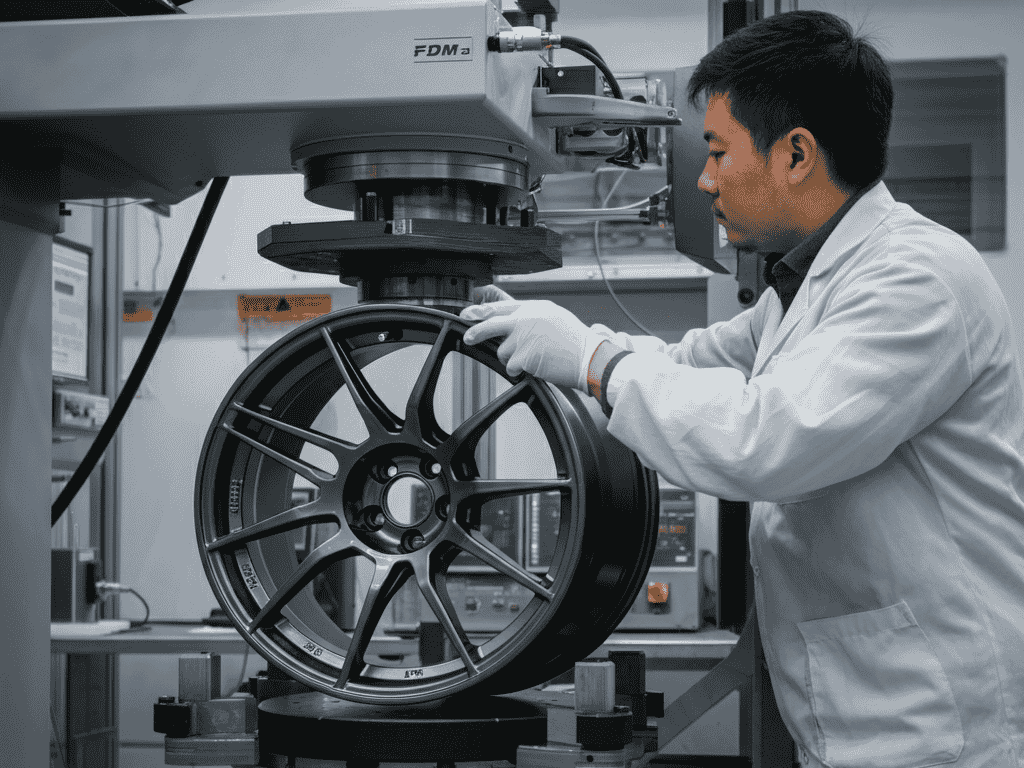

When something like a sausage curb bends a rim or paint gets discolored due to severe brake heat, the message is relayed back to the CAD drawing and the test stands.

It is not glamorous, but when the wheel you take home reflects thousands of heavy-duty miles that you did not have to pay extra for.

Speed, Cost, and Strength Balancing- Manufacturing Methods

Not all wheels are created equal, and JDM Wheels give you options that map to your budget and use case without forcing compromises you’ll regret:

Forged monoblock: Using a single piece of high-quality aluminum, it is pressed at great force, grinding the grain in one direction, enabling the wheel to become thinner without losing strength.

Think old-school six spokes that look minimal, but upon examination, a lot of weight has been pulled out of the hub pad and spoke roots.

Blister steel, flow-formed (rotary forged): Cast in the center and spun and formed under heat.

This provides extra density in the places you require and at a cost less than complete forging. It is popular in cars, daily driven, and racecars enjoyed on weekends.

High-quality casting: Proper casting, including heat treatment and X-ray, can be excellent for street use.

The difference with JDM Wheels is the discipline around molds, cooling profiles, and post-cast testing.

In these techniques, you will find intelligent decisions such as shot peening to enhance the fatigue life, T6 heat treatment, as well as tight balance specifications that will minimize the use of balance weights your shop has to attach to your rim.

The net result is a wheel that turns straight and can take the torque as well as most heavier wheels I have tried thus far, and does better on the potholes than any other wheel I have so far tried.

Philosophy That Handling Fitment First

A lot of mass-market wheels are after appearance, and they just worked out the geometry on the secondary level.

JDM Wheels are different. They are designed with brake clearance, scrub radius, and sidewall tire support in consideration.

Offsets are selected to keep the area of money where the chassis is happy, not where a fad sends it.

On a car such as the Civic Type R, 86/BRZ, Skyline/GT-R, and S-chassis, the most popular sizes fall right where the suspension feels planted, in that the width is wide enough to run a true performance tire, the offset is enough to clear the multi-piston calipers.

Of course, the barrels are designed against flexing at high lateral load.

Another fan-favourite: hub-centric bores and tight centre tolerances.

Hub-con tightness ensures less vibration, better quality feedback through the wheel, and less stressing of studs.

Combine that with knurled beads on certain JDM Wheels, and you get tires that stay put under high torque or heavy trail braking. The vehicle is relaxed, and one can lean more easily on it.

Standards, Testing, and Stamps that have Meaning

You’ll hear folks mention JWL and VIA when they talk about JDM Wheels.

JWL is a Japanese wheel and tire safety standard for light-alloy wheels; VIA is a test program that ensures that the wheel used actually performs the same as the manufacturer specifies.

The acronyms are easy, but the battery of tests associated with them is not: they are cornering fatigue, radial fatigue, and impact testing, to simulate the abuse of wheels in reality.

To provide margin, many Japanese makers run well beyond the minimums, running an extra cycle and loading up.

In search of a pleasant overview on wheel load rating, sizing, and how they all join together Tire Rack Wheel Tech library is one of the best openly accessible sources on the web, with schemes and easy-to-understand guides ( Tire Rack Wheel Tech library )

When a brand puts out test stamps and supports with unreligious lightweight specifications, you can shop confidently instead of shooting in the dark.

It is a Timeless Design Language

Why will as many as six spokes with straight lines and mild concavity continue to play 10 or 20 years after they were born? That configuration places material where the forces are moving and keeps the stress paths short.

JDM Wheels lean into these fundamentals. These iconic examples of the blocky six-spoke that is carved out of billet, the multispoke that folds into a barrel, the twin-spoke that gives room to brakes to breathe–they are not just fads.

They are structural choices that are only incidentally made in a way that they appear correct.

The amount of care can also be detected in finishes at a close range. Hard-anodized lips resist chips, semi-matte surfaces conceal light scuffing on track days, and high-quality clear coats are much better off on a winter road than budget products.

When the finishing stands the test of time, the wheel continues to look good, and resale value follows, as will the strength of the wheel.

Resale Value and a Quality-policing Community

The market realizes the feeling of products. JDM Wheels often sell quickly secondhand because buyers trust the metallurgy, testing, and fitment track record.

Restricted releases and collaboration releases are not something that can hurt.

Counterfeiters have a harder time as authenticity stamps, laser-etched serial numbers, and branded air valves are on the way.

Fakers are often called out by the community early and frequently, and that network effect guards against faked value.

It is a beautiful moment when you open a box, and the barrels are straight, there is no indexing on the faces, and the hardware goes on with a smooth thread.

You have many more chances to get this with the well-known Japanese brands.

How You Feel in the Driver’s Seat

Nobody talks specs, the road does. Swap heavy factory wheels for a quality set of JDM Wheels, and the steering picks up detail.

Speed at low speeds becomes smoother due to the fact that the suspension system does not struggle with additional weight. It switches on turn-in with less hesitation in the direction taken by the nose corrections in mid-corner reductions.

Braking makes the car settle more quickly. All this does not transform a daily into a race car, but the concomitance is significant, consistent, and repeatable across platforms.

On track, heat management is also of concern. Tough barrels and smartly vented spoke webs ensure brake temperature is controlled.

That makes pads wear out slower and rotors crack not as easily.

And by selecting a tire that fits with the rim width well, so that the sidewall is well supported, you will find it easier to position the car at the limit.

These are the silent benefits that make laps sweet and keep your spirits up.

Buying Guide: Pick the Right JDM Wheels for Your Car

Start with goals. Everyday wear with infrequent canyon runattle requires flow-formed or forged designs that allow cost savings and weight reduction.

Show uses, or heavy brakes, often warrant a fully forged wheel with stiffer barrels and profiles to clear large calipers.

Know the figures. The four essential bolt patterns, center bore, width, and offset. Know the hub size in order to select hub-centric fit.

Check caliper templates with the manufacturer of the larger wheels. A width to match your tire spec with a 245-section tire fitting well around an 8.5-9.0-inch rim and a 265 liking 9.5-10.0.

Level assessments of mind load. Most performance compacts and sedans offer a lot of head space, but the heavier crossover and grand tourers put a greater weight on the wheel.

Look for clearly stated ratings; JDM Wheels from established brands are usually very transparent here.

Consider tires and alignment as one. A quality wheel deserves a tire that suits your use and a proper alignment that will protect the tread and sharpen response.

If you are making the car wider or altering offset, expect a relatively minor alteration in alignment to keep the car happy.

Maintenance plan. Clean, good wheels will endure a long time. Automotive brake dust, road salt, and tar have the capability of eating away finishes.

A quality pH-neutral cleaning solution and a soft brush go a long way. Valve stem and hardware are vulnerable to heat on track days, so check/re-torque after each heat cycle.

Common Myths Around JDM Wheels Cleared Up

Forged wheels are unbreakable. Others. Forging increases strength at a comparable weight, although a heavy blow, such as a pothole or a curb can compromise any wheel.

The idea is not to be invincible but to have better toughness and fatigue life per kilogram.

Their cast wheels cannot be serious. Owners of such cast wheels will not ride on them. Not so. Higher temperatures and correct heat treatment of a cast and well-known brand mast enable it to accept everyday beating and a healthy driving attitude.

Many JDM Wheels use casting where it makes sense and reserve complete forging for applications where the performance benefit justifies the cost.

And lightest is the best of rentada. Very light wheels are often fantastic on smooth track, but real life throws unpleasantness like rough shoulders and broken pavement at your wheels.

Any balance weight should be done using barrel force and the paths you travel along. That extra ounce, to produce a stronger barrel, can save a rim under real-life conditions.

Any spacer is bad.” Hub-centric spacers of high-quality torqued properly can eliminate clearance issues without fuss.

That said, the cleaner solution is choosing JDM Wheels with offsets and caliper shapes that fit your car in the first place.

How Big Names Continue to significant Wins

The companies pay fetish to iteration, Enkei, ADVAN Racing, Work, WedsSport. They refine spoke roots to eliminate stress risers, optimize knurled patterns to eliminate tire rotation during extreme launches, and machine hub pads to provide better mating.

They are likely to lay out actual weights of typical sizes, which are not airy at as, only to fit a single narrow size. Trust levels when spec sheets run with independent scales at shops and at track paddocks are established rapidly.

Other, less obvious benefits are parts support, Center caps, valve stems, replacement stickers, and even hardware are available years after release for many JDM Wheels.

By keeping authentic center caps and new valves, you also avoid the knowledge (or suspicion) that at one time, someone just curbed a rim and attempted to make it appear brand new again.

Fashion with really no Trimmings

Great designs are not shouty. They are even in all directions, the brake hardware is brought to the fore without overshadowing, and the surface cleaning is not a problem. The use of concavity is to solve clearance, rather than follow a trend.

Lip depth is done with geometry, not through a pursuit of a catalog image. JDM Wheels tend to nail that balance.

Park beside the same car on budget rims, and you will notice in the way the spokes blend with the barrel of the wheel, the sharpness of machining, and the depth of polishing.

The color preferences are also on durable and classy colors such as metallic gunmetal, race bronze, semi-gloss black, and diamond graphite, among limited colors, for those who like variety.

Even back then, shade selection tended to match up with factory paint shades, so you did not need to repaint the car in order to use the wheels.

What of Clones and Counterfeits?

Once a model is popular, it will be copied. The easiest way to stay safe is to buy from authorized dealers and inspect stamps and labels that genuine JDM Wheels carry load ratings, size, offset, and a maker mark.

Prices that look too good to be true are usually too reasonable to be true. The other is weight: weigh the wheel. The same can be said when a generic 18 x 9.5 model weighs about 18-19 pounds, and the same wheel reportedly weighs two or three pounds more, setting the alarm clock.

You are putting the responsibility of holding the car at speed into these parts. Corner-cutting does it now and may cost you a lot in the future.

Fine-tuning the Whole Package

Big wheels make other additions stand out. Combine JDM Wheels with quality tires, fresh brakes, and a sensible alignment, and the car feels like it gained a complete chassis refresh.

Steering loading reduces, the vehicle becomes more stable, and even fuel economy can increase a few percent in a steady-state cruise because you are not doing as much work, rotating masses.

The repetition of good barrels and consistent bead seating also allows tires to break in before losing their tread throughout an entire session, and will enable them to stay close together from lap one to lap ten.

Longly Picks: Real-World Picks of Popular Platforms (Guiding Ideas)

Civic/Integra: 17-18inches diameter, including the 8.5-9.5 width range on modern Type R/Si platforms. Look for JDM Wheels that clear big factory calipers without spacers and carry hub-centric bores that match Honda hubs.

R86RZ: 17×8 or 18×9 to allow scrub radius-friendly offsets. Many JDM Wheels offer caliper-friendly barrels for Brembo-equipped trims.

– 18 to 20-inch wheels, paying special emphasis on brake clearance. Forged sets work here; the cars are heavier, and they respond to stronger barrels.

Miata: The wheels made of light metal revamp the vehicle. 15-17-inch diameter with diameter of a moderate width makes the car lively and sensitive without touching.

These are not complicated rules, but they are initial points where you can improve your shop using real-life caliper format and chassis intentions.

FAQ’S

1) Are JDM Wheels good for daily driving?

Yes quality JDM Wheels are engineered for strength-to-weight and typically meet JWL/VIA standards.

In street applications, forged or flow-formed are better due to their better durability with reduced unsprung mass, which offers a better feel of the steering and brakes.

Select a load rating sufficient to run confidently above the vehicle axle weight, use hub-centric fitment, and keep the finish (use pH-neutral cleaners, regular rinses) to lengthen life.

2) Forged vs. flow-formed vs. cast: which JDM Wheels should I buy?

Forged: Strongest-in-class weight and stiffness of barrels; suited to track or heavy cars and/or big-brake clearance.

Flow-formed: Sacred ground of where most enthusiasts experience the balance of lighter barrels and good durability at a better price.

First-rate cast: They are OK as daily driver provided they are adequately heat-treated and tested; give priority to well-established brands with verifiable specifications.

3) What size and offset work best when upgrading to JDM Wheels?

Start with the brake clearance and hub bore and then tile out tire width to wheel width (rule of thumb is tire section width pairs well at approx. 0.9-1.1 times wheel width in inches; e.g. a 245 tire fits best at an 8.5-9.5 wheel width).

Select an offset that maintains scrub radius and fender clearance; in 8.5 to 9.5″ width, typically between +35 and +48 are found on many sporty platforms, but always check the template provided by the making.

Once installed, have a wheel alignment to maximize steering and tire supports.

4) How can I spot genuine JDM Wheels and avoid counterfeits?

Purchase only through licensed vendors and check: proper JWL/VIA markings, clearly visible size labels, laser etched serials, and maximum weight that corresponds with the brand stated specification (copies tend to weigh more).

The quality of packaging, finish and hardware (valves/caps) must be OEM quality. On the other hand, when the price is unrealistically cheap it normally is.

The Bottom Line: Why JDM Wheels Keep Winning Hearts (and Laps)

Combine all of this: engineering, worthwhile testing, intelligent manufacturing, fitment that satisfies handling, verified standards, and designs that ensure well-aged. Then you get a product that is much more than skin-deep.

JDM Wheels aren’t magic; they’re the result of thousands of tiny choices made by teams who care about how a car feels when it loads into a corner at the exact point your pulse climbs.

You will notice the difference each time you turn the wheel, whether you daily a hatch or head out some weekend in search of PBs.

If you just began search today, take some time to read about unsprung mass at Car and Driver, and study the diagrams in Tire Rack Wheel Tech library.

Compare sizes, weights, and load ratings to compare and then choose the one that best fits your roads and your objectives.

The right JDM Wheels will make your car sharper without harshness, confident without drama, and stylish without noise exactly what good parts are supposed to do.

[…] JDM Rims for an automobile can be compared to an accessory on an outfit. For the Japanese Domestic Market (JDM) culture, this […]