Steeped in a culture of innovation and competition, these engines are the product of unmatched craftsmanship and desire to push boundaries.

Table of Contents

Here, we explore seven compelling reasons why JDM engines stand unrivaled in power and reliability.

From the ingenuity behind Honda’s high-revving VTEC to the legendary durability of Toyota’s 2JZ, we delve into the distinctive attributes and cultural influences that make these engines so exceptional.

Discover how JDM engines consistently outperform larger and more expensive counterparts through meticulous design and a philosophy centered on constant improvement.

Join us as we uncover the magic that makes JDM engines not just automotive components, but feats of engineering excellence.

A Culture Of Engineering Excellence And “Kaizen”

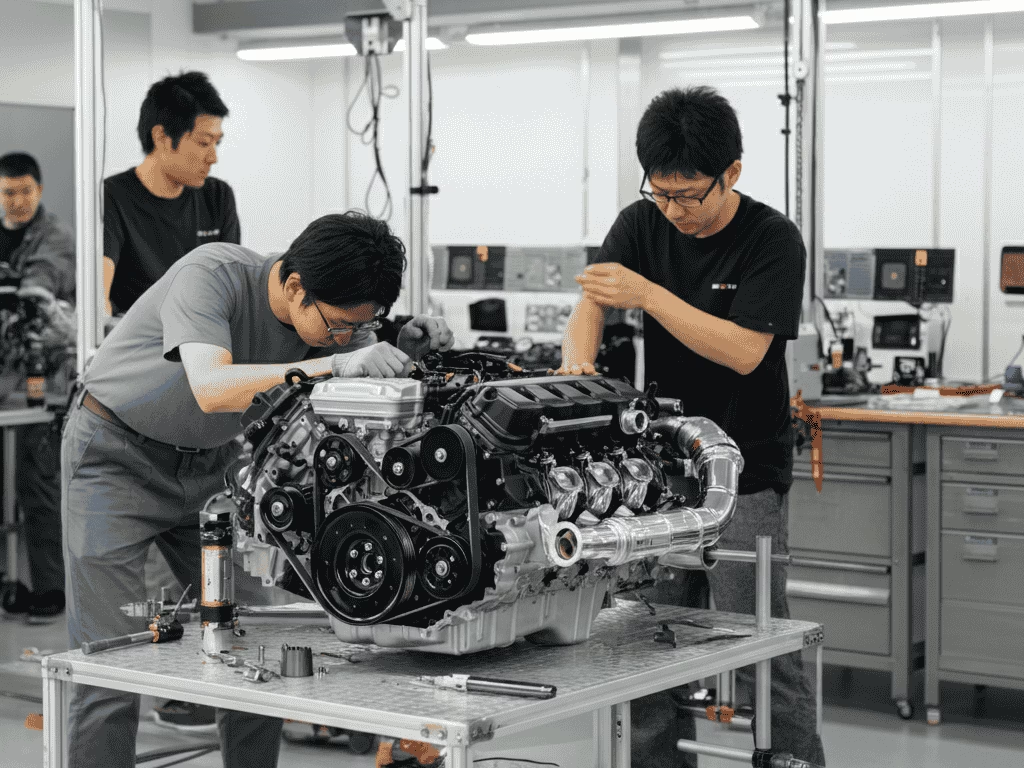

At the core of Japanese manufacturing is the philosophy of “Kaizen,” which translates roughly as “continuous improvement.”

It isn’t just a corporate buzzword but a deeply embedded cultural principle that imbues every phase of design and manufacture.

For Japanese automakers, engine construction is a continuous process of refining and improving.

Every last small bit produces gracefulness and refinement in design. This philosophy is responsible for the serial revision and upgrading engines seen in many JDM makes. Take Nissan’s RB line.

RB20 was new, but thence came the fabled RB26DETT, a twin-turbocharged straight-six that was the heart of ‘Godzilla’ (Skyline GT-R).

This progress didn’t just happen. It was the upshot of many hours testing, analyzing and finicking over. Engineers obsessed with details, from block alloy composition to head oxygen flow characteristics.

This kind of obsessive attention to fine detail results in engines that are built to very tight tolerances, with typical measurements as low as 10 micrometers for certain components.

When the components fit together precisely to the level of a molecule, the engine runs more efficiently, produces more power, and can cope with greater stress.

This is one of the fundamental reasons why many JDM engines can take large increases in power from aftermarket modifications without having to undergo extensive internal strengthening. The base simply comes so well built

While other manufacturers may focus on cost-cutting, Japanese automakers have traditionally placed greater stress on the quality of their engineering, believing that better products will ultimately win out.

This devotion to excellence is what anchors the standing of all JDM engines.

The over-engineering design philosophy is directly responsible for the lasting appeal and performance of JDM engines.

Stories are commonplace in the car tuning community of a 2JZ-GTE running 1,000 horsepower on a stock block or a Honda B-Series engine lasting decade after decade under heavy abuse. This is not mere gossip; it is something much more concrete.

During the late 1980s and 1990s bubble economy period, Japanese automobile manufacturers would design their performance engines for much more power than stock trim levels. There are many reasons why this would happen:

Homologation Rules Many iconic JDM cars competed in racing series such as the Japanese Grand Touring Championship or Group A rallying.

Manufacturers were required to produce a certain number of road-going versions of their race cars in order to be eligible Rob pointed out that for this reason the engines are based off detuned racing models.

In other words they were originally built to last in a motorsport environment. For example, the cast iron block on a RB26DETT is designed to withstand the type of loads seen in endurance races.

At 1989 the big four Japanese automakers reached a consensus that was enforced until 2004.

The “Gentleman’s Agreement” restricted advertised horsepower figures to 280 PS (or 276 hp). However, engineers continued developing ever more powerful engines during this period and simply detuned them for sale within Japan.

So the actual potential of these JDM engines is substantially higher than what they were allowed to advertise.

The JDM Supra with its 2JZ-GTE was rated by Toyota as 276 hp, but with a few small modifications to the catalyst and boost control it could easily release more than 350 hp without any difficulty. The real performance capabilities of this model had been purposely hidden.

When you think of reliability, think Japanese. Japanese brands have built a reputation across the world over time for their excellent quality engines and tough machines.

And for the many thousands of miles down these engines run without missing a single beat.

It was this kind of experimentation and design philosophy that laid the foundation for tuners to create engines with unimaginable power outputs.

Many offer this service overhauling their heads or intakes for increased flow are just two examples but not all go so far as building entirely new engines from scratch.

Furthermore, Japan is under no pressure to build any cars or engines of this sort for its home market.

Innovations That Transformed Performance

Innovating has been what Japanese engineers have never lacked in confidence over. They have often been ahead of the pack for example, the soaked electrode spark plug, a creative solution to make engines run smoother or with more power.

This was some 30 years before anyone else ever tried this technique in earnest; and now it has become standard practice throughout automotive manufacture worldwide.uptime per liter of displacement.” Advanced lightweight materials Atsushi Niimi This could be like putting the technology on supercars first.

Lexus, in particular, is on leading edge of this sort of thing with their LS 450h luxury sedan and now even GS 450h hybrid executive saloon turning.

Low rolling resistance tire technology Some car companies want to increase their amount of hybrid vehicle sales dramatically.

IMO, efficient rolling resistance tires that also work well and feel fine to drive with on the street will indeed help make such fall wins Celebrate 20, 000 electric cars on China Road 23Guiding customers at a special day for the faithful, The Standard reports 365 days a year-likely over 50% of Hong Kong residents each own an EV or at one time had bought a EV protecting families at their tailgate

VTEC (Variable Valve Timing & Lift Electronic Control) from Honda is perhaps best known.

Back in the late 1980s, VTEC was a monumental innovation that allowed the same engine to have two completely different camshaft profiles.

Initially, at low RPMs, the engine uses a mild cam profile that provides quiet idling, good low-end torque, and fuel efficiency. As the RPM begins to increase, the system transitions by switching to a high-performance cam profile.

This change significantly increases airflow, resulting in a powerful surge of high-RPM power. The result is an engine that seamlessly combines everyday usability with the excitement of high-performance driving.

Thus drivers could have their cake and eat it, of sorts A docile commuter engine in one package and a high-strung race engine in another.

Sites such as HowStuffWorks offer animated explanations for more technical details on how VTEC operates.

This is why JDM engines like the B16B or K20A are famous for their exciting, high-revving character and power-to-displacement ratios beyond anyone’s imagination.

Some other JDM-engine milestones

Twin turbocharging: The first such systems appeared in the mid-1980s with the Porsche 959, Mitsubishi Starion ESI-R, and Dodge Lancer ESI, with only three cars out of seventeen models sold in North America today employing some form of this technology.

Popularized by the Mazda RX-7 (13B-REW) and Toyota Supra (2JZ-GTE), this system employs a smaller turbo for quick response and low-end torque at low RPMs. Once the revs start climbing, though, a second, larger turbo takes over to deliver a massive surge of top-end power.

This complex but successful setup enjoyed a broad, usable power band. It was very effective, and single-turbo systems of the time, often struggling with either lag or limited top-end power, could not achieve this result.

Intelligent Engine Management JDM ECU (Engine Control Unit) technology was ahead of its time. These systems could control every aspect of an engine’s operation: fuel, ignition, boost pressure and variable valve timing.

They were ahead of anything out there in terms reliability and performance optimization under all conditions. This sophistication also provided a solid platform for aftermarket tuners to work from, re-mapping and extracting even more potential out of the engine.

Rotary Engines From the moment the Wankel rotary engine was conceived, and Mazda began its exclusive production, rotary engines have been its ticket to unopposed success.

The 13B-REW with twin sequential turbos from the FD RX-7 was a compact, lightweight powerhouse capable of turning out over 250 horsepower from just 1.3 liters of displacement.

Its design, seen nowhere else with its comparative lack of moving parts and super high redline, lent the RX-7 distinctive characteristics combined with razor-sharp handling balance.

These technological leaps enabled car-makers to challenge the old saying that “there’s no substitute for cubic inches”. They showed that clever design could triumph over brute force.

The Tuner Culture and Aftermarket Support

But a great engine isn’t enough. It is the huge, all-consuming, passionate and unshakeable global tuning culture which transforms JDM engines from good to legendary.

From the first days of street racing on Osaka’s Wangan highway to the post-millennial world of grip racing, tuning Japanese cars has been a central part of the food-chain.

This created a positive feedback loop between manufacturers and the after-market. Tuners recognized the potential in these over-engineered JDM engines and started developing parts to release it.

Companies such as HKS, GReddy, Tomei and Endless emerged, providing a complete ecosystem of high-quality performance components covering everything from turbochargers or exhaust systems to forged pistons and fully programmed engine management packages.

This fantastic after market backup has four main advantages:

END OF DOC

Knowledge Base: Over decades, an enormous worldwide knowledge base has been built up by tinkerers and testers alike.

Online forums, YouTube channels and specialist magazines all offer help sheets for tuners, dyno runs, figures that are not on the books and what it really costs in terms of performance when you go off-stage on your engine like that one guy who sees every hill-climb attempt through to its bitter end.

If you have a question about modifying a 4G63T or SR20DET, the chances are that thousands of people like you.

Proven Power : Engine technology from Japanese automakers has gone through its paces under the aftermarket’s whip, being taken to its absolute extreme limits. The 2JZ, for example:

If it can be made to produce over 1500 horsepower for race competition or circuit use and does so reliably, then at all levels of tuning confidence in this engines layout will naturally emerge.

The aftermarket effectively tests these engines on a global basis.

The world of JDM performance cars is a unique subculture within the automotive aftermarket.

This richly textured world differentiates JDM from other tactics and engines.

It has ensured that JDM engines are not merely a forlorn aspect of the car media of great yesteryear but decisively realized potential products.

Yet today their collective muscle keeps them dominant even decades after rolling out to factory floors around the globe ming them no laggards in comparison with their newer brethren which started afresh after them.

High-Revving Nature and Power-to-Weight Ratio Very large numbers of loved JDM engines rev high.

While a conventional V8 might be running out of puff at 6,000 RPM common industrial wisdom holds that a Japanese four-cylinder or six-cylinder can easily work well past 7,000, 8,000 or even 9,000 RPM.

Honda’s F20C engine from the S2000 series, for example, came with a staggering 9,000 RPM redline as standard.

This high-revving nature is epitomized in the meticulous design of featherweight, balanced components like pistons, connecting rods, and crankshafts.

Lighter parts mean less inertia, an advantage when a motor is quickly changing speeds and reaching higher RPMs.

This design philosophy stems from the concept of volumetric efficiency. Horsepower depends on torque and RPM.

By maintaining good torque at higher RPMs, more horsepower is produced.

This results in several advantages:

- Outstanding Specific Output: JDM engines are renowned for their high specific output, the output of horsepower per liter of engine displacement. The F20C accomplished 240 horsepower from a mere 2.0 liters. This introduces a specific output of 120 hp/liter. At the time of its launch, this figure was higher than that of any other naturally aspirated production engine. It remained the world record for years. This efficiency reflects elite engine design.

- Better Driving Experience: The screwly shaped engine offers a richer and more thrilling driving experience. The sense of an engine coming “on cam” and pulling hard to its redline is a feeling driver can not give up. This is what makes vehicles like Honda’s Integra Type R and Civic Type R so desirable.

- Better Power-to-Weight Ratio: In many cases, compared to engines with comparable power, JDM engines are smaller and lighter. A light rotary or inline-four engine can provide better total vehicle weight balance, which is critical for excellent handling and cornering performance. A lighter car needs less power to be fast, and JDM engines have mastered this art of the synergic link between engine and chassis.

Thanks to its attitude of making cars as light as possible and giving them a high-revving engine, the result is a Japanese racer that seem easy to handle, quickly adapts when asked for more speed.

In many cases such vehicles can outmaneuver heavy, muscle cars with much more power and heavier bodies.

The upright stance and immediate throttle response of these Japanese sports cars are just two hallmarks that make your heart race each time you drive one.

- Performance That’s In Balance: Whether it’s the acceleration g-forces created when your JDM car pulls away from a standstill or counteracts as you turn right or left, that special feeling when driving a Japanese sports car is due mainly to its overall performance balance key.

Inline-Six and Four-Cylinder Heaven

In the same years that car makers abroad were producing McLaren F1’s in V8s, Toyota sought a new major source of power: the inline-six layout–which Mazda likewise had for their RX7.

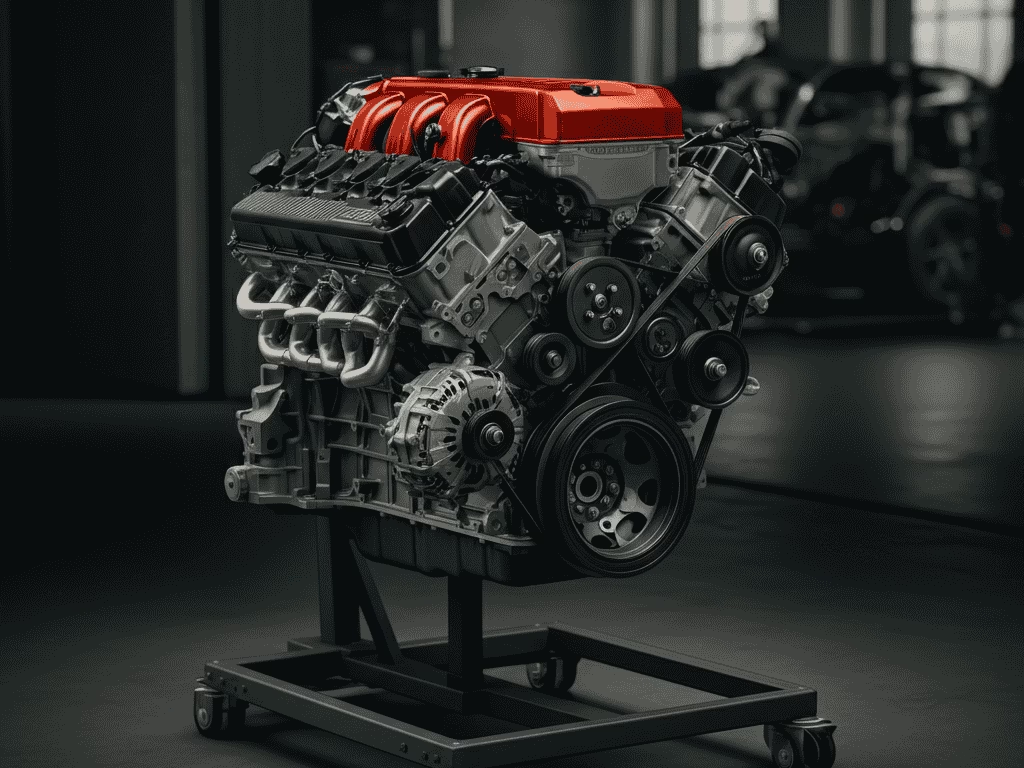

- The Inline-Six Greats: Few engine types are as balanced as the inline-six. The primary and secondary forces are in perfect balance, resulting in a very smooth and very compact powerplant that is highly efficient. It is this smoothness that allows the engine to rev easily and with less strain on its internal components. Japanese engineers decided they could not improve on a design like that and so took a step up to make it an art form.

- Toyota 2JZ-GTE: The undisputed King of All Inline-Six Engines. Its sequential turbos, rugged cast-iron block and seven main bearings combined to give it strength, low-speed torque and smoothness all in one package

- Nissan RB26DETT: A further icon. This engine featured “individual throttle bodies” (a feature heretofore reserved for exotic supercars) and was cast as a racing engine from the outset. It was this power plant that contributed to Skyline GT-Rs overwhelming dominance on circuits around the world.

- Nissan L-Series: The forerunner of the RB, the L-series engine in the Datsun 240Z was an in-line six that was simple, robust and easily tuneable. It was just such an engine that put Japan’s sports cars on the map.

- The Four-Cylinder Leaders: And at the other end of the spectrum of JDM factories was just as impressive a lineup in its wonderfully-smooth four-cylinders. These little powerplants demonstrated so well that big power does not neccessarily have to come from a large number of cylinders.

Honda K-Series (K20/K24)

This is one of the most popular four-cylinder engines ever built. Taking the old head gasket problems with the VTEC engines as well as rev hang one step further, K-series can dish out massive amounts of torque from below 2000rpm and yet still rev to the sky.

Mitsubishi 4G63T

The engine that powers the Lancer Evolution. This iron-block, 2.0-liter four-cylinder turbo is beyond robust and can take much over 800 horsepower of boost pressure without problems.

Because it was originally designed for rallying, the engine was constructed to suffer hard caltrops, water crossings and even launches down mountainsides.

Nissan SR20DET

The heart of the Silvia and 180SX, the SR20DET was an aluminum-block, lightweight turbo four-cylinder engine.

During the drift boom it became the engine to have thanks to its readiness for power tuning and extreme reliability.

By using these examples, Japanese manufacturers were able to create a suite of JDM engines that was not only powerful, but also perfect for the lightweight, balanced sports cars they motored.

For more details on the history of these iconic powerplants there are also many online sites, such as Speedhunters community which provides articles and content for those who want to learn about their heritage.

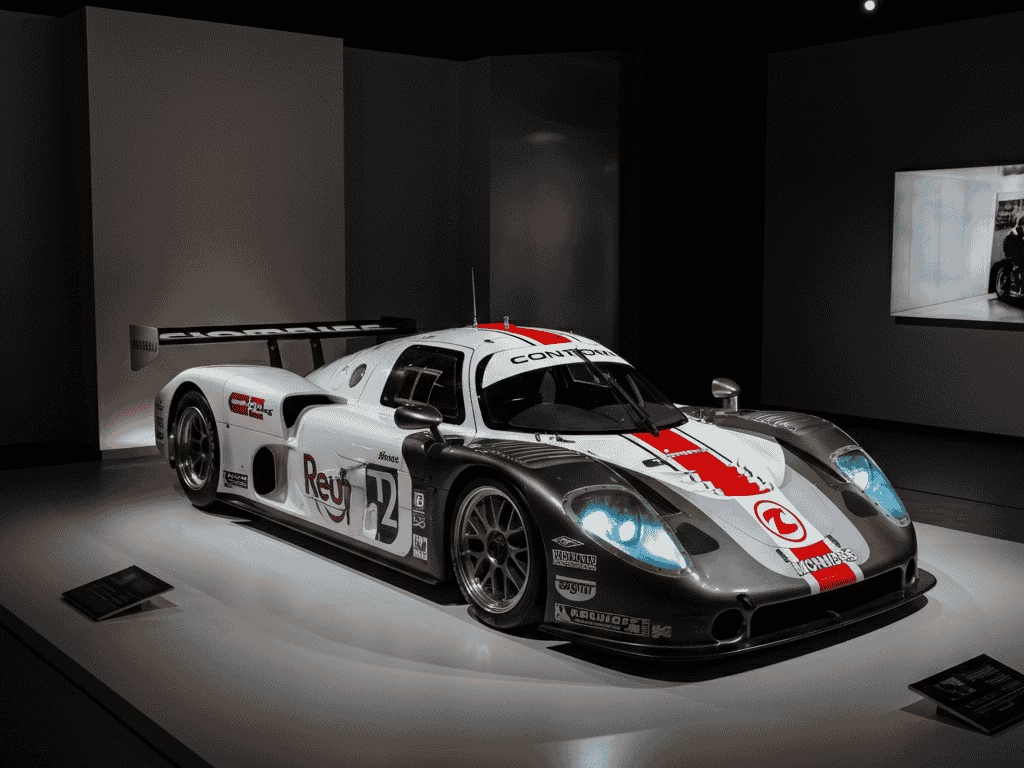

A Legacy Forged in Motorsport

The best place to put an engine through its paces is the racetrack. It is there that weaknesses show up and true strength can be measured.

JDM engines were so successful in almost all forms of motorsport and have established a legacy that is inextricably tied to racing.

In contrast with stuffing success stories about racing engines into car adverts, this was no empty hype: lessons learned from the track could be directly applied to the development of mass-produced powerplants. These motorsport victories translate to features and characteristics a daily driver enjoys today.

- Touring Car Racing: Starting in the early 1990s, the Skyline GT-R (R32), tried and proven to the bones, became so dominant in both Group A endurance and touring car races held both in Japan and Australia that its shorter nickname was simply “Godzilla.” The car’s performance was so good that it finally got banned. The precision and control developed in such competitive settings mean today’s JDM vehicles offer exceptional handling and stability, qualities that make them reliable and safe for everyday commuting.

- Rallying: The World Rally Championship (WRC) became a battleground for Japanese manufacturers. The Mitsubishi Lancer Evolution (powered by the 4G63T) and Subaru Impreza WRX STi (powered by the EJ20) in their furious race to outdo one another pushed the turbocharged, all-wheel-drive cars they were based upon to a peak level of technical sophistication. These molten hot JDM engines were designed to churn out explosive power and be reliable in the worst conceivable conditions. As a result, even typical JDM models have durable, high-performance engines that can handle diverse terrains and weather conditions on regular streets.

- Endurance Racing: Mazda did something that many people thought impossible at the 24 Hours of Le Mans. In 1991, with the four-rotor R26B-powered Mazda 787B, Mazda was able to outright win a race that had been only for piston engines since 1923. It remains the only non-piston engine car ever to win the prestigious event, and this early triumph of the rotary will go down in history. This victory shows why today’s drivers enjoy engines with longevity, requiring less frequent maintenance and offering reassurance during longer road trips.

- Drifting: Drifting, a sport that was born on Japan’s mountain touge roads, in those days merely proved a natural breeding ground for cars like the Nissan Silvia (SR20DET), Toyota Corolla AE86 (4A-GE), and Toyota Chaser (1JZ-GTE). These JDM engines gave drivers high horsepower, fast response, and the reliability required by this challenging form of motor sport. The agility and responsiveness perfected through drifting now manifest in the smooth acceleration and responsive steering enjoyed by modern drivers, making city driving and quick maneuvers a thrilling experience.

JDM engines are powerful for many other reasons too. For one, those engines are incredibly durable.

An engine strong enough to live through twenty-four hours at Le Mans or a series of punishing rally stages is certainly no slouch in traffic or on the track! This races-proven heritage is your guarantee of JDM engines’ absolute performance and reliability.

It’s Not Just Metal It is high-precision craftsmanship, that’s the secret of the world-beating power plants nurtured by JDM.

Conclusion More Than Just Metal

The success of JDM engines comes from many factors combining to create the right sort of “society”, knowledgeable attitude and willing to devote time that it takes.

It was begun by people who followed a very simple principle: Kaizen, the striving for perfection endlessly repeated over each new iteration until every last nut, bolt or cam was redundant; they were over-engineered and practically hand-made into existence.

With a solid footing like this, JDM powerhouses have gone on to absorb new technologies and ideas and thus emerge stronger than ever before.

Engines such as VTEC and sequential turbocharging, techniques further explored in the following article “Advanced Charging Technologies for Smaller Engines”, have redefined what smaller displacement can be capable of producing.

Cascading met The glory of JDM engines not only generated a world-class culture with items to buy after market, but in addition created something transcending all expectations: a giant support system nourishing these engines that goes on unlocking extra horsepower for future generations.

Specializing in lightweight, high-revving designs, the perfection of four-valve and six-valve inline engines resulted in products that were not merely powerful, but with buttery response as well as a perfect set of complementary characteristics for the cars they powered.

Above all, that entire tradition grew up and proved its mettle on the track where JDM engines by the late 1990s were sweeping all before them from rally stages to endurance races.

Even decades after their birth, Japan domestic power units are still at the top of their game. For both performance and dependability, reliability and flexibilities..

Today, albeit your possibilities have broadened with electronic control this much remains always the same.

With its wonderful sound and awesome power, this “golden age” of JDM engines exemplifies the heart of every vehicle out there.

Exotics and sports bin cars from Italian to English, BMW to Buick are powered four-fold with a proud yet humble J-spec engine.

Driven by constructor passion rather than executive mandates these machines carry two more keys to personal effort and responsibility. Even now when gears are strictly electronic actors direct their long-standing legacy inspires car enthusiasts around the world and fires their dreams.

[…] pulse of this world is the JDM Engine. These marvels of engineering are more than just mechanical components they are crafted with a […]